Hypercube Developer Website

Synthetic AI Hand Project

Project details: Synthetic AI Hand Project |

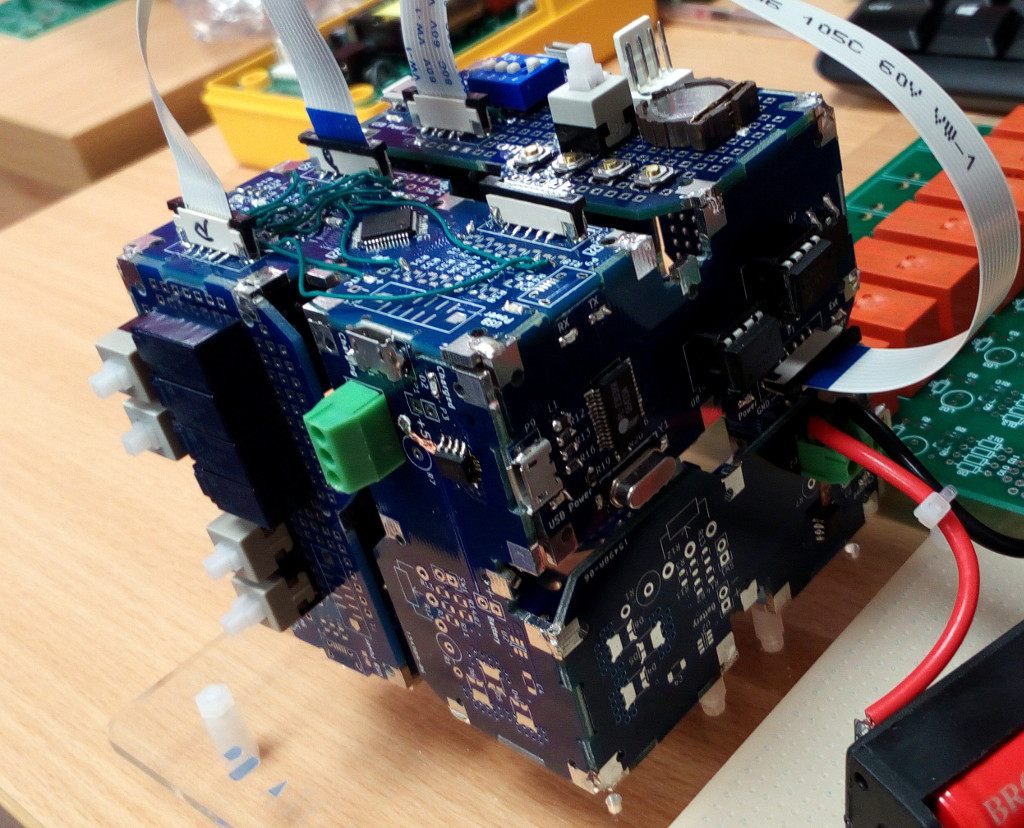

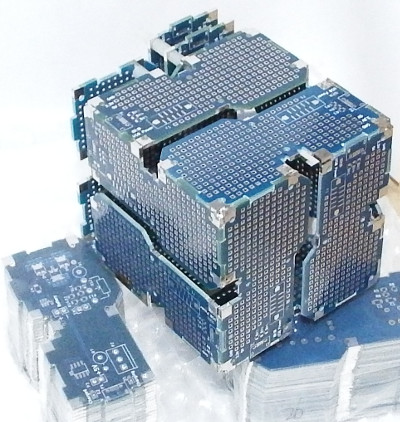

The rational behind a Synthetic AI Hand Project is straight forward. The entire human race civilization is built by a pair of hands duplicated over and over again doing the little things that collectively becomes civilization. So if we could make a pair of really good AI infused synthetic hands, only one pair of hands would ever get built, and the rest are all just duplicates. Steps: 1. The infrastructure for Synthetic AI Hand Project begins with Hypercube Tesseract PCBs that make all the relevant peripherals connected to the CPUs that drive the actuators. 2. A second piece of the infrastructure is the software for designing the AI hand 3D printed parts which is scripted and written in Python running under Linux. The purpose of printed parts is to create complex wax mold copies from which the final parts are cast. The wax is dissolved by applying heat and recycled.  First 3D Printer Three 3D printers as above have been acquired and a large one capable of 400mm x 400mmm x 500mm prints with dual head. The smaller printer prone to jamming because the linear bearings are impossible to assemble correctly aligned due to a design mistake. An option is to design and print replacement parts for the linear bearings before trying to assemble the remaining printers. The large printer arrived with borosilicate glass plate broken. Local replacement supplier found that can make the 400mm x 400mm x 3mm thick borosilicate glass. The dual head printer was chosen because one head can print ABS while the other prints PVA, a water soluble support material. The support material is dissolved away with water speeding up the 3D printing process which would otherwise require a lot of time to remove support material. The software running on the PC is Repetier running under Linux which connects through USB to the controller board on the 3D printer. The control board is an Arduino. The power supply that comes with the printer was determined to be weak, so a bench power supply capable of sourcing ample current at 15V was used.3. A third piece of the infrastructure is the test bed that takes feedback from different hand designs and alter the scripts to make incremental improvements with each iteration. The test bed is driven by Linux programs written in Gambas with a GUI interface to make it function easily. 4. A fourth piece of the infrastructure is to make the test bed portable by making it work on ARM SoC boards like the Pi so that it can be fitted to Androids that can transport it to places of testing and work, so it may be tested in situ under real work conditions. 5. We need to think about how to solve social problems with increased automation and AI with UBI (Universal Basic Income). The best way to UBI is through VAT and regulating against use of VAT for any other political projects. With the rapid onset of the Technological Singularity that creates automation and AI at a faster and faster pace, the pressure to change society such as implement UBI will get stronger. Join us on Twitter

#HelloHypercube

to follow the project

|

Hypercube PCBs come with their own interchangeable software to mix and match functions as needed. Designed around IoT needs, we make prototyping work fast and effortless. |

| | Home | More | | ||

Electronics Store Opening Soon |

||

Copyright (C) Hypercube Semicondutors 2018 |