|

Home Page

Six Transistor Cache

Investors

Launch Date

Contacts

Terms and Conditions

_________________________

|

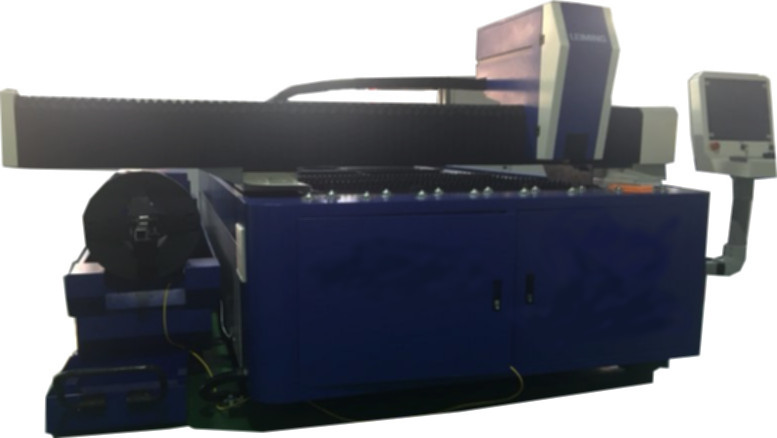

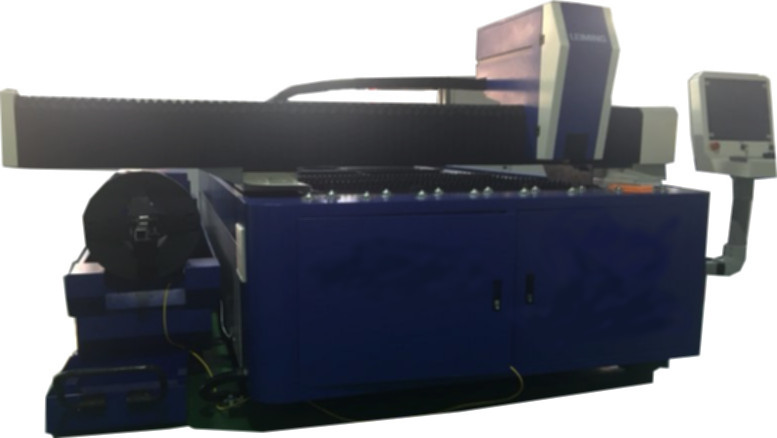

Fiber Laser 500W / 1000W / Tube Cutter

- Energy Efficient 100,000 Hour Fiber Laser 500W and 1000W

- Approximate cutting thickness rule 1mm/100W for Carbon Steel, 0.5mm/100W for stainless steel and titanium

- Cuts Aluminium and Copper (0.3mm / 100W, 0.2mm / 100w respectively - with increased laser light reflection damage risk)

- £34,999 for 500W laser, £49,999 for 1kW (+ VAT)

- £49,999 for 500W with tube cutter, £64,999 for 1kW with tube cutter (+ VAT)

- The tube cutting machine can be used to hold any profile from square to L shapes and T shapes ranging in size from 20mm to 140mm

- Cut profiles with slots and bolt holes and then assemble them into large structures

- Make your own machines and jigs with these high strength profiles

- These are high tech energy efficient fiber lasers for clean manufacturing environments suitable for high tech products such as IoT devices and Industry 4.0 manufacturing

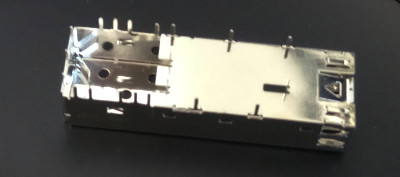

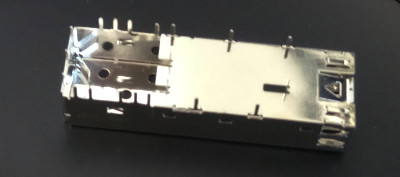

- The ideal use is to make products and cases ranging in size from PC size steel case size product to tall refrigerator size products.

- Example use - build battery case for 10kW batteries for electric car / solar charger

Build an outdoor vehicle charger

Make a giant 3D printer

Make solar panel frame to hold panels

Build delivery drones and delivery robots

Make warehouse robots

- Laser can be used to cut small thin steel sheet and fold with press brake to make cases for electronic modules.

- In above example, the designs can be made parametric so that you could type in the dimensions of the box and number of legs, and it gets turned automatically into a drawing ready for laser cutting. These auto generated drawings save a ton of time.

- An energy efficient Fiber Laser is the ideal product you need to make the next generation of low plastic content metal products.

- To make complex metal structures out of sheet steel, you will also need spot welder to weld sheet metal parts and a press brake to fold metal parts.

- With these 3 simple tools, you can reduce the time it takes to make prototype machines from months involving contractors to just days using a combination of these three tools and software driven to auto generate products.

- You should reserve about 5m x 5m for materials handling and the machine

- You will also need parametric design software.

- Free software such as FreeCAD have modules for sheet metal working and solid modelling and this machine is fully compatible with all standard outputs.

- With modern methods of working, you can skip hand eye coordination for creating drawings, and instead opt for scripted design which is likely to be 100% accurate every time.

- Hand eye coordination always leaves room for errors while scripting can be 100% accurate.

- Use Python scripts to generate DXF cutting patterns parametrically so that holes and slots are in the right places when products scale.

- These Python scripts sit behind a web server and accept web page input of dimensions, create the relevant dxf file, which can then be downloaded through the web interface.

- You can commission us to write Python scripts for your product to reduce the overheads of customizing your product.

- Simply enter the dimension and the DXF files are created in a second with all the holes and geometry 100% correct

- So if you make a 10kw electric car battery, and want to scale to 100kw, just type in 10 to get 10kw and 100 to get 100kw and spend 10 minutes more getting it all cut !!

- This is the future of high tech parametric design. Instant reactive one click manufacturing and we are here to help you participate in this new world.

- No more waiting for someone to find a time slot to fit you into their queue and send it by post which can easily end up losing days for every iteration.

- You might be a metal working shop. So what can we do for you to get more orders with Industry 4.0?

- Industry 4.0 means there is much more of a deep connection between manufacturing and automation through software.

- If you want us to set up web upload of files and quotations, we can help you fully automate the quotation system to convert inquiry to an order within minutes so you can cut and dispatch same day.

- We can also help with sourcing parts to complete projects more quickly.

- Our China investor is located in the middle of the most productive engineering basin in the world - the Guangdong Province.

- Guandong has Shezhen which is the biggest electronics market city in the world, as well as all the supporting infrastructure for items such as stepper motors, bearings, electric motors, pneumatic components, Lithium batteries, solar panels, generators, power electronic components, sheet metal, metal mesh, stamping machines, dies for stamping machines, nuts and bolts, rubber seals, drag chains etc.

- We can help source all these items along with the Fiber Laser to get you to manufacture products at fastest possible pace to get your product into volume production.

- We supply the Fiber Lasers for manufacturing 4.0, and with it also all the infrastructure needed from electronics to mechanical parts and the infrastructure to move into parametric manufacturing and for taking online orders because we also function as a similar company.

- Industry 4.0 means there is much more of a deep connection between manufacturing and automation and we will engage with you at this new level.

- Industry 4.0 implies your company must make its presence felt in the online world of Internet as well as the manufacturing world.

- And that means interfacing your manufacturing systems as well as the products you make into online systems so that it can be accessed more widely.

- If you are making an electric battery charger, its no longer sufficient just to make a charger with hose to plug into your car.

- You need most products to connect with the mobile phone to accept payment and tell users with a notification system the current status of your system.

- In this instance, you can tell the user when the battery has charged and the vehicle is ready to be driven away to free up space.

- We can help with this integration by amassing a whole list ready made technology that we can transfer to your product.

- The days in manufacturing old style are limited. It is no longer sufficient just to take phone orders, cut the parts and deliver some 3 days later. You will end up losing orders.

- Better option is to plan to have a web site to upload files, cost them automatically, and instantly give a quotation and if the customer accepts, then take the payment and send the files to the machine to start cutting.

- As the future arrives, even this simple scenario is not enough.

- Customers will want a range of products and a range of ways to customize the product.

- Typically for example, a customer can order 1000 pieces of stainless logo cards.

- He/she may choose to add a bottle opener and hex nut spanner holes as well.

- And he/she uploads a photo file for the logo, they may add a ruler along an edge as well if your web site offers more customization to attract visitors.

- If you haven't got the staff to design these kinds of extra convenience items to take more orders, then customers will walk to where they can this kind of service is available online with instant gratification.

- So we are here to make sure that if you make the effort, your online presence and its usefulness is felt all over the world for the products that you make by taking customized orders online.

How to use fiber lasers to make accurate machines

- Laser are incredibly accurate at cutting but the edge is not smooth and adds +/- 0.1mm accuracy. The greater the depth of cut, the less accurate the final pieces - may be +/-0.3mm.

- A lot of metal machinery such as steel cases, fencing, brackets, have no problems with +/- 0.1mm to +/-0.3mm accuracy.

- Where products require a tight fit, it is possible to cut a sample piece of steel, measure the final width, and adjust the laser cutting profile dxf file to get within +/-0.05mm accuracy. The pieces can then be fit very tightly with a rubber mallet. This is typically called an interference fit and it is supremely efficient for producing tight fit. For metals it is also possible to apply heat to expand a hole and/or apply cold to shrink a male part to fit a hole. As the parts change temperature to room temperature, this type of interference fit can become extremely tight and strong.

- For high speed machinery such as gears, more accuracy is needed.

- The standard way is to machine it and grind metal parts to their correct dimensions.

- With fiber lasers, there is another way which requires far less machinery.

- With a fiber laser, it is possible to cut small pieces of tool steel, polish a cutting edge on to it, and fit into a steel frame to make a reamer.

Each piece of the reamer is slightly smaller in size by about 50 microns (it can be smaller or larger).

After cutting an approximate shape such as a gear wheel, stack a few, apply oil, and push the gear wheels through the reamer with hydraulic pressure. It will remove a few tens of microns at a time until the pieces coming out the other end of the reamer are exactly to required size and profile.

Custom made reamers with fiber lasers offer the lowest cost method of high volume production of accurately made parts.

You can commission us to create the reamer generating software in Python and make it server based.

Support Infrastructure

- The Fiber Lasers can be purchased with immediate phone support, spare parts holding, and on site engineering support. What kind of support you need is down to how you plan the use of the Laser. If it is constant production, then you want a full support package to get the Laser back on line as soon as possible. If it is more of an R&D environment, you may be OK with phone support and 48 hour replacement parts.

Ordering

|