|

Home Page

Six Transistor Cache

Investors

Launch Date

Contacts

Terms and Conditions

_________________________

|

Hypercube Developer Website

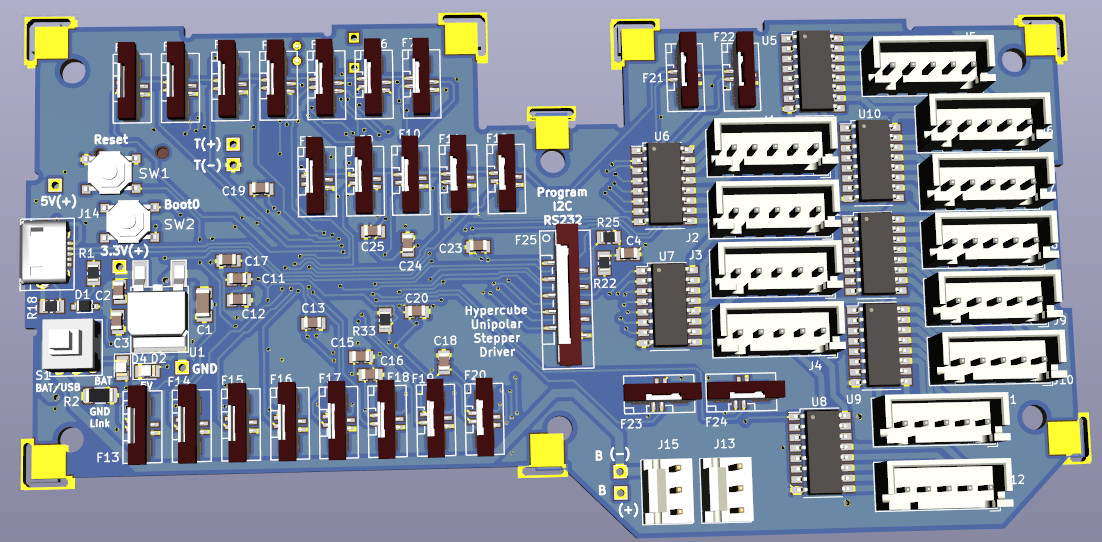

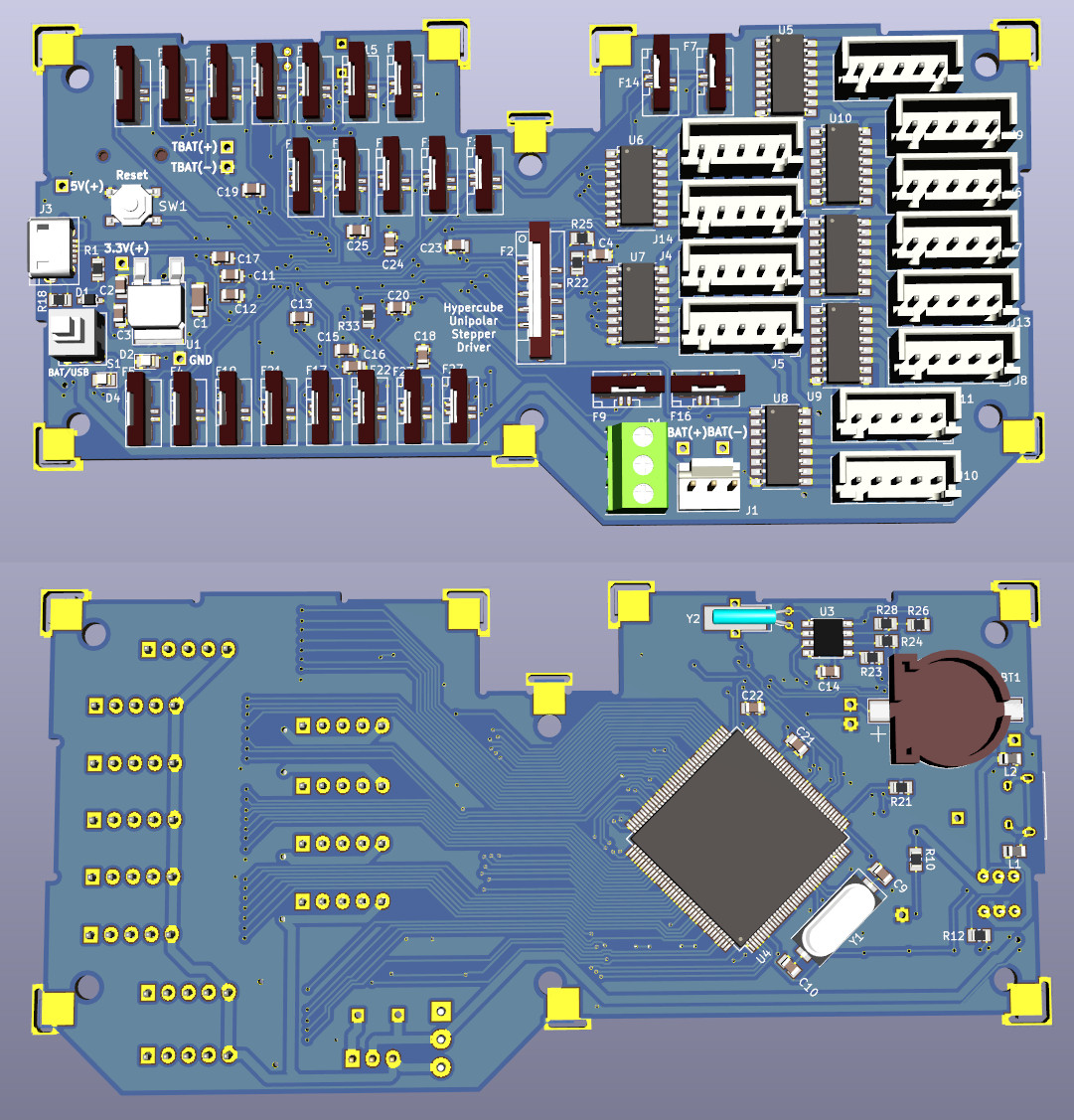

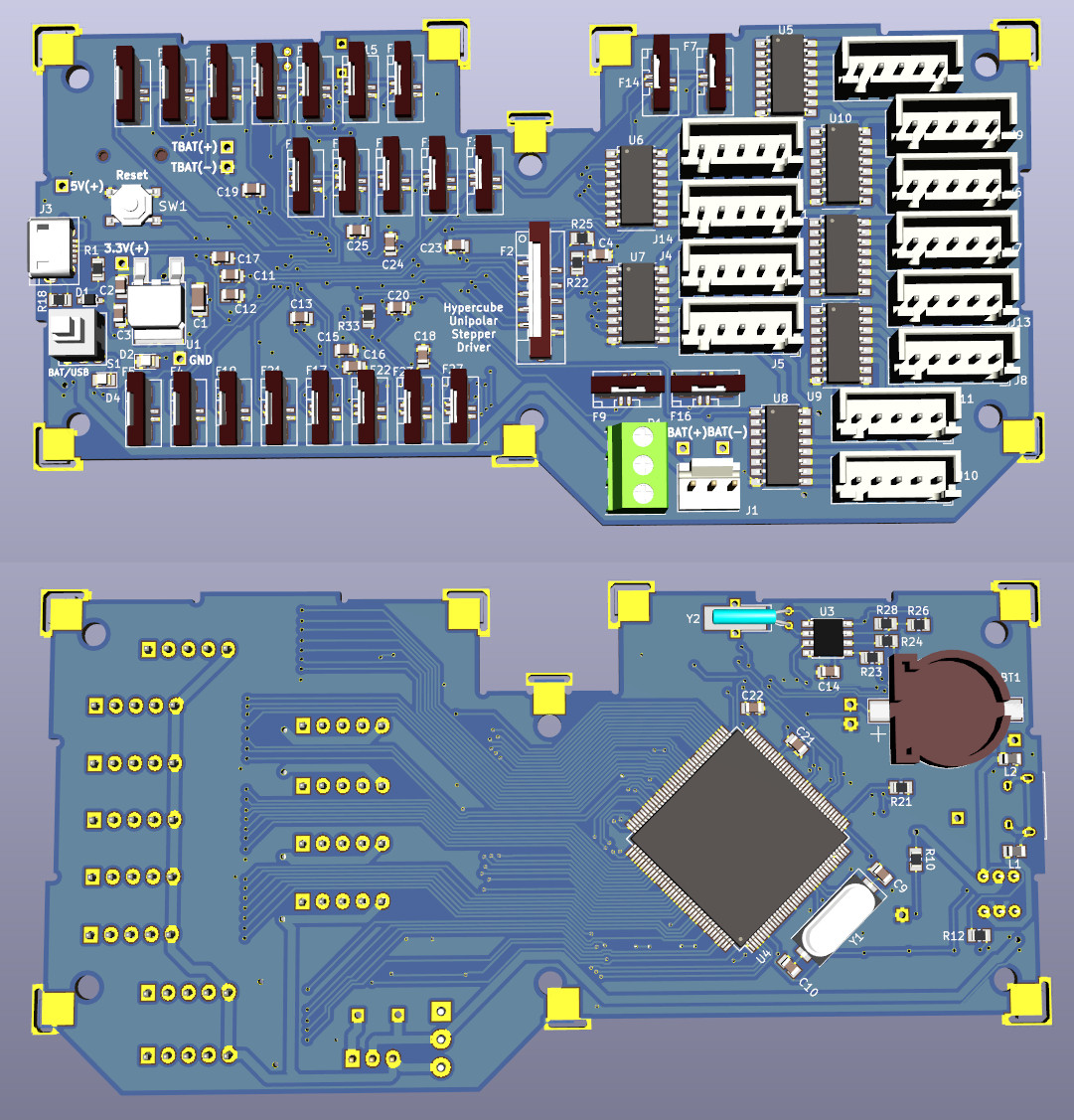

Hypercube Unipolar Stepper Driver Board

2018-11-11

- Final version of Hypercube unipolar stepper driver board

- Small tweaks to make it more user friendly including adding a power mixer.

History

- Design finished for a unipolar stepper driver board - ready to be sent for manufacturing.

- This board has a big CPU that can handle 12 unipolar stepper motors like the 28BYJ-48 which is driven by ULN2003A driver chip.

- The board has 24 sensor inputs. Each sensor input has 4 wires connected to 4 pin vertical FPC. Two of those wires as power, the remainder can be say an optical interrupter limiter switch such as ITR9608, and remaining one wire is free.

- Good for robotics, animatronics, hydroponics, transforming furniture, etc. 144 motors can be controlled from one fully populated Hypercube.

- We will write the full open sourced multi-tasking drivers in Arduino code and/or C code to control all motors simultaneously and sense the 24 limiting switches and a dozen or so thermal sensors.

- The interface to the board is I2C, USB serial, serial and it will be fully documented.

- Regardless of interface we will write a uniform shared memory communications protocol which will be supported by all CPUs

- The shared memory masks all details of physical implementation of the communications link.

- The user is presented with a shared memory area where multi-tasking programs can read and write and it will transfer to the remote CPUs that are attached throughout the Hypercube with multi-tasking drivers that the user does not need to learn or understand.

- With this method, the user does not have to worry about trying to write code for every different kind of embedded hardware out there.

- It is possible to make high speed custom bus communications - example is a 32 bit bus running at around 10MHz directly between high pin count CPUs. The details of this custom bus is still masked through the shared memory communications driver which present all communications links one uniform shared memory bus without having to know the details of how the driver is implemented or what physical pins are doing all of the time.

- The shared memory interface is self contained. The user does not need to add additional variables to remember the state of each communication link. They are already present in the shared memory interface.

- The board has a battery backed time chip - allows it to operate motors on regular timed basis - e.g. water plants.

Developing with Unipolar Motors

- Small unipolar motors such as the 28BYJ-48 come in a range of voltages such as 5V, 12V

- Using higher voltage implies lower current usage - useful for projects with large numbers of stepper motors

- Unipolar motors are not as strong in generating torque as bipolar stepper motors but they are cheaper and can come with a gearbox that allows high torque to be generated.

- Unipolar motors such as 28BYJ-48 have no magnets inside - instead they have steel elements which are similar to the steel body that is magnetized by coils.

- Because this type of motor relies on magnetizing steel, they can get hot with prolonged use.

- Because there are no magnets inside, the cost of the motor can be kept very low.

- These motors are produced in huge quantities for all kind of applications by a lot of different manufacturers and thus it is economical to use steppers inside a project for precision.

- The 28BYJ-48 comes with a variety of gearboxes, but typically they rotate 2048 steps with one full turn.

- The maximum pulse rate also varies with motor, but typically 500 steps a second is doable.

- As the speed is increased, the torque fades away and the motor will starts skipping steps depending on the load.

- At 500 steps a second, the motor shaft turns with reasonable good torque - for example it is hard to stop the motor turning by gripping the shaft.

- If used with a lead screw, the motor can move a good amount of weight. For example you could make a robot chair that slowly wobbles the seat so that you don't sit comfortably for more than 20 minutes in any one position that might cut off your circulation.

- The motor is powerful enough to open drawers, curtains, windows, hatches, wardrobe etc. If you add additional gearing it can fold away items like beds and furniture if you choose to automate them and make it robotic furniture.

- Another use is in creating special electromechanical display similar to kinetic art. With the addition of motors you can keep kinetic art mechanisms in motion indefinitely with solar power for example. You can also make the piece do near impossible feats because of the availably of power assist to keep the mechanisms going. You could make a big planetarium for example in your ceiling and it would quietly run with the aid of these motors.

- Each fully populated Hypercube can control 144 motors and you can keep adding more Hypercubes until all the elements of a really complex work of art, science and engineering are realized. The resulting machines can be high in mechanical density facilitated by FPC wiring for the sensors. Each motor has two end stop sensors to help make the motor remain within the end stop constraints of the design. They can be connected to optical interrupters such as ITR9608 which will work for a very long period of time without mechanical wear. There is a sync line on the connector to synchronize and coordinate all motor activity which helps if there are many boards in the system. It can serve as a common error line so if multiple boards are orchestrating a complex mechanism, and a fault develops, then all the other mechanisms can be stopped instantly by pulling the sync line low.

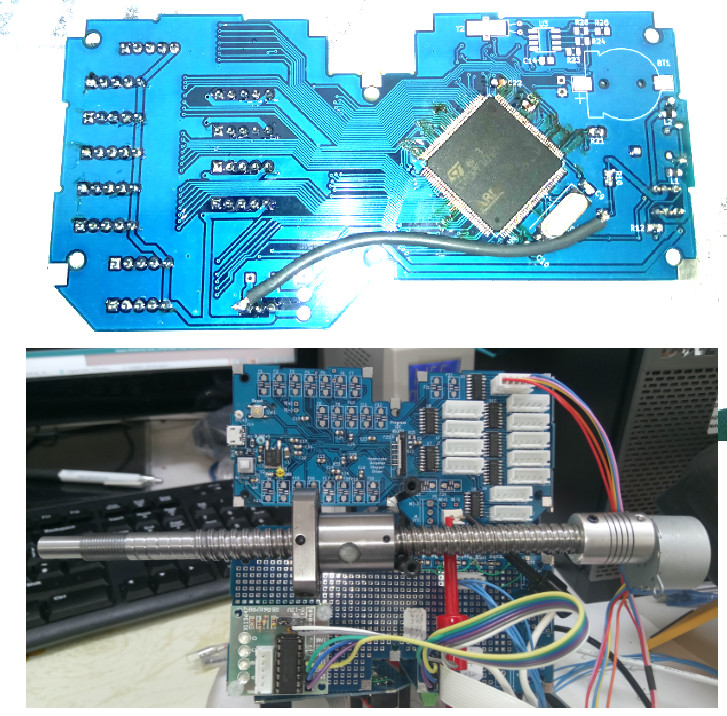

2018-08-10

- The board has arrived and it boots OK. Code can be written on Arduino IDE or on AC6 compiler (ST's free Eclipse based IDE and compiler that works under Linux)

- Tested running with a 12V 28BYJ-48 stepper motor attached to ball screw with 2ms (500Hz) stepping speed.

|