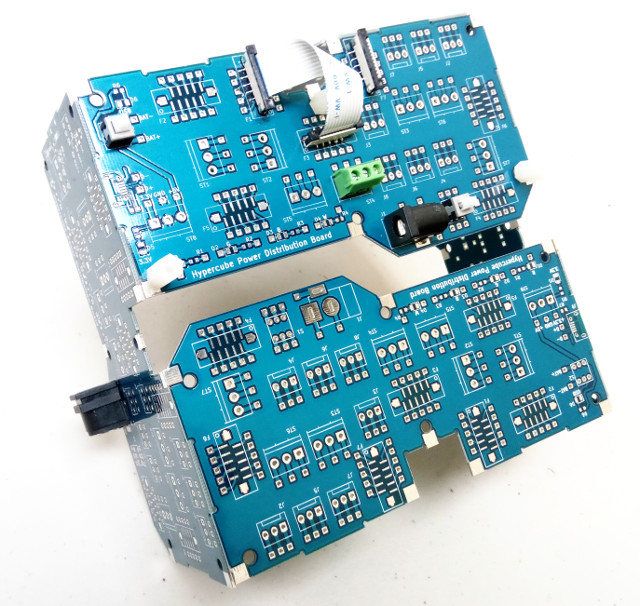

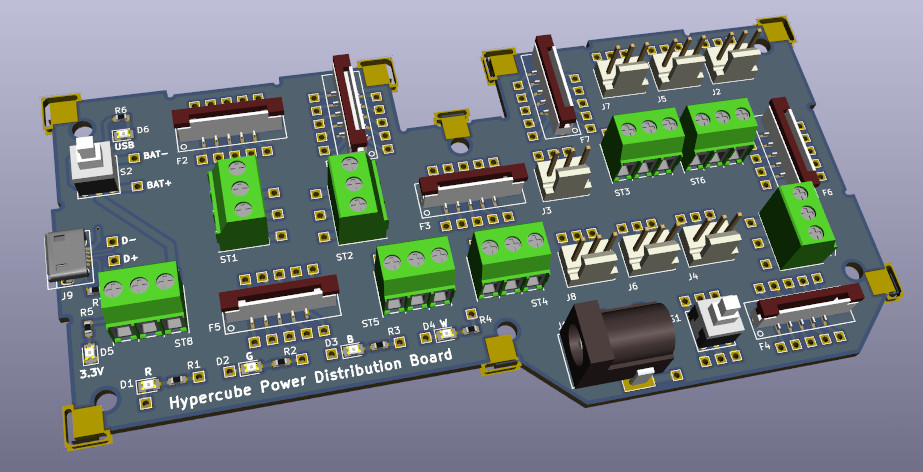

Hypercube Power Distribution Board

- This board has numerous connectors to connect different power sources together

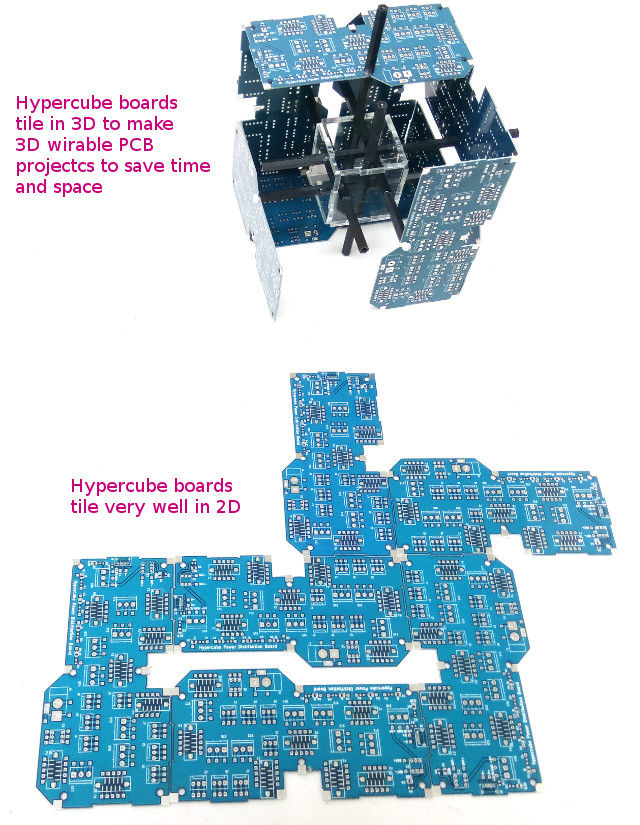

- The box can be built by soldering the corners together as illustrated below, or by fitting it to a cube frame as illustrated above

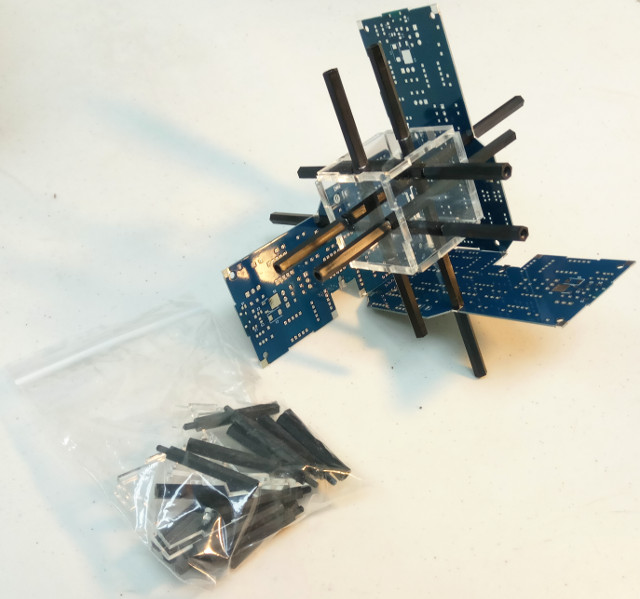

- The Hypercube endoskeleton kit arrives.

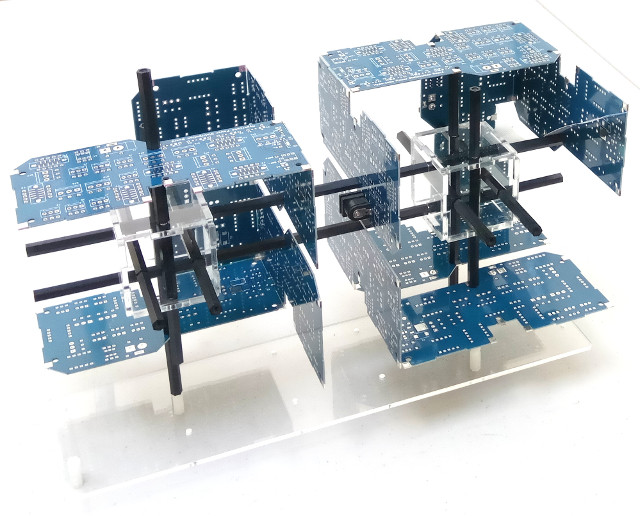

- Hypercube boards can be soldered at the corners to join them together into a stable cube box, or they can be screwed to an endoskeleton built from a ready made kit with hex spacers and 6 acrylic cube plates.

- Also no need to fully close the box with all 12 PCBs to get structural stability when using the endoskeleton for support.

- This is necessary in circuits that require ventilation, noise reduction, and/or fit inside a bigger box where space is at a premium.

- The acrylic cube can also be made from PCB. For smaller machines such as drones, it adds valuable PCB area for electronics. For larger Hypercube, the acrylic cube is replaced by metal box that can house within it power supplies. We also built the inner cube with power supply and gigabit ethernet switch so that we can add networking for a 3D wired data center ready Hypercube.

- Hypercube boards tile very well in 2D. A project can be fully assembled on a flat bed. They can then be tiled into 3D compact Hypercube form and wired together in 3D with the built in 3D wiring conduits.

- The perfect PCB contours were generated by software written in Python. Even a 0.1mm difference in the numbers results in a Hypercube box that does not close. The whole board was all made in KiCAD. Below is KiCAD rendered image of final board.