|

Home Page

Six Transistor Cache

Investors

Launch Date

Contacts

Terms and Conditions

_________________________

|

A Car That Travels 4x Speed of Sound With Floating Magnetic Wheels In a Hyper Tunnel

- The Hyper Car technically has only 4 moving parts - its 4 motors which operate in frictionless mode floating in a magnetic axle.

- The speed of the Hyper Car is limitless but aerodynamics will prevent it traveling at any great speed.

- Take away the atmosphere, run the car in an evacuated Hyper Tunnel, then the speeds achievable is limitless until material properties intervene.

- The Hyper Car in a Hyper Tunnel can easily achieve 4x speed of sound with an autopilot driving the car.

- The rolling resistance of wheels is only 1 or 2 percent, but in a evacuated tunnel, the rolling resistance is the major resistance that needs to be dealt with. Air weighs 1kg per cubic meter and all that needs to be moved when driving in air. But not in an airless Hyper Tunnel. There is no air, so the effective rolling resistance is biggest issue that needs to be dealt with, and that is why the Hyper Car with wheels floating from a magnetic axle is the most convenient solution inside the Hyper Tunnel, while outside the tunnel, the Hyper Car drives like a normal car on wheel (or if driving at high speeds, it can be driven on magnetic axle for better ride comfort).

Hyper Tunnel Design

- The Hyper Tunnel is installed by walking robots that walk the pipe sections to their destinations.

- The ends of the Hyper Tunnel tube are not welded to the next section.

- The tubes terminate in a big rubber O-ring.

- The O-rings are maintained under pressure by O-ring compression actuators and sensors to allow the metal tube to expand and contract into it without releasing the vacuum.

- This allows the tube segments to expand into the O-ring during the heat of the sun.

- Each of the segment joints have glass rings to allow passengers to view out of the ring as they drive very fast through the ring.

- The evacuated tube is made of steel with a laser running on the side of tube to keep it straight as it stretches in the sun.

- The tube is powered by solar panels covered 360 degrees taking in the ambient lighting as well as direct sunlight.

- Cleaning and inspection robots travel the length of the inside and outside of the tube keeping it maintained whilst being powered up by solar power charging stations.

- The Hyper Tunnel is raised off the air and maintained at its correct level with laser precision and actuators located on the pillars.

- They Hyper Tunnel is safe for the countryside, farms and animals as the pillars are raised above the ground.

- The Hyper Tunnel pillars are robotic machines in their own right.

- The Hyper Tunnel pillars are kitted inside with robotic mechanisms to move themselves out when replacement arrives.

- The Hyper Tunnel pillars are not rooted to the ground and require very little ground preparation for fastest possible deployment.

- The Hyper Tunnel pillars are designed to accommodate sand storms, rain storms, floods, snow, ice etc.

- If the ground below a Hyper Tunnel sinks, then more legs are set down and/or more anchors are drilled to root the pillar to the ground more firmly.

- Only one superior Hyper Tunnel pillar is designed, and the rest are duplicated to save costs and take on the benefits of mass production.

- The purpose of walking the Hyper Tunnel sections by robots is to avoid building roads everywhere that in itself take time and a lot of resources including fuel. By walking the tunnel sections to their destination, the ground preparations are minimal. This is not too dissimilar to how railways are built. A large part of the railway is carried by rail to the construction end. The walking robots will initially be built in miniature designed in parametric format and scaled up. As many pieces as possible are made from flat sections cut by plasma and/or laser cutters and welded to make the final machines with minimal machining.

First Customers

- The first customers for Hyper Car tunnels may become Middle East where there are deserts, oil cash, and willingness to invest in advanced technology. Another possibility is snow covered regions like Northern China and Alaska where there are people, and there is commerce to be developed despite the hostile weather.

- The Hyper Car would connect cities together in minutes and would leap over the sand dunes without the inconvenience of sand/snow entering the cars and its internal mechanisms.

- There is plenty of sunshine to allow batteries to charged and for the whole length of tunnels to be covered with solar panels to generate and sell electricity.

- Other countries that may benefit from investment is China - its simply got all the resources to build these kinds of systems in a short enough time period and bridge a vast country with Hyper Car Tunnels that link cities in tens of minutes journey time.

Hyper Car Design

- The Hyper Cars are longer than normal cars by about 2 to 3 times and appear more like a stretched car.

- The range of the Hyper Car is minimum 2000 miles in a Hyper Tunnel because it is driven in an evacuated tube with frictionless axle motors.

- The range of the Hyper Car is about 600 miles in normal traffic.

- They Hyper Cars carry a electromagnetic traction control system on the underside to manage how the machine sticks to the floor whilst being driven at high speed in an evacuated tube.

- The electromagnetic traction control system also allows Hyper Cars to absorb power from the Hyper Tunnel and charge the batteries from the tunnel if running low on power.

- The powerful batteries take up a third of the car.

- The frictionless operating mode only kicks in after Hyper Car has gained speed. Without speed, the Hyper Car rests on normal bearings.

- The driving of the Hyper Car in the Hyper Tunnel is managed by an autopilot.

- The sensors inside the Hyper Tunnel relay information to the Hyper Car miles ahead and apply brakes if there is a problem long before the Hyper Car reaches the problem.

- The Hyper Cars are made of Carbon Fiber mixed with Titanium which is light weight and so good it is resistant to permanent damage from low speed collisions.

- The internals of a Hyper Car are a dream to make because there are only 4 major moving parts and none of those interfere with interior design.

- Most likely the interior is made with laser cut panels for rapid production.

- The initial Hyper Cars are likely 3D printed and the rough surfaces pinned with laser cut paneling.

Uses

- The Hyper Cars and Hyper Car Tunnel systems are show case futuristic technologies to link cities that demand future arrives early.

Integrated Manufacturing covering batteries and magnets

- Because the battery technology and magnet technology contains valuable minerals, we would build car manufacturing plants in a holistic way.

- We aim to attach electronics to every battery (i,e, 'chip' every battery), monitor its health, and get it returned for replacements.

- Similar thoughts go out to the magnets.

- We would aim to service the battery ourselves by knowing the battery and the chemistry with the chips bolted to the battery.

- Using historical data recovered from the battery, we would be able to work out which battery mixture survived best and under what circumstances such as weather.

- Same for magnets.

- We would work with manufacturers of batteries, magnets to ensure that we use their product in best possible way and give them valuable feedback to improve their batteries and magnets.

Progress

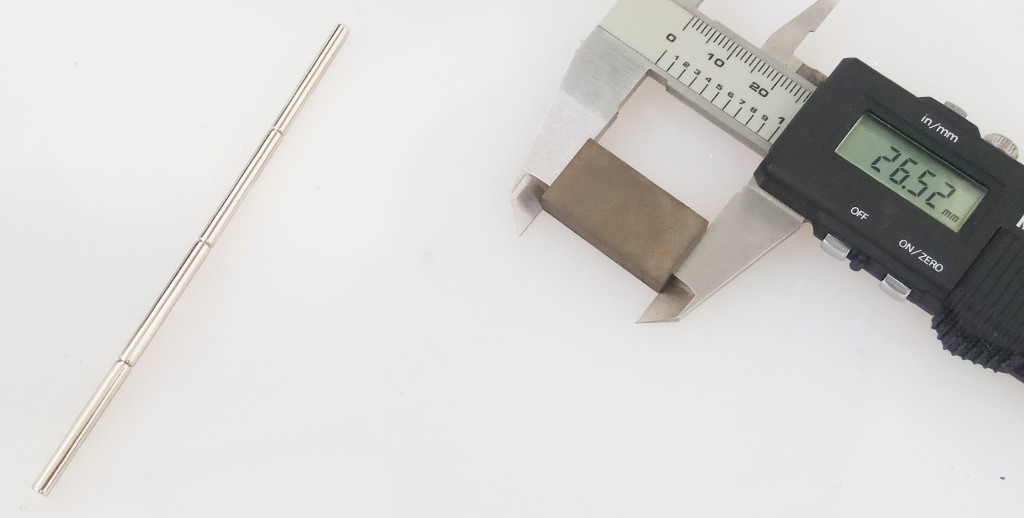

- We already make the floating axle motor samples and it works 100% with no speed limit which means it functions like an electric jet engine with potential to bat air faster out of an engine than sound at hypersonic speeds. It is lightest of all motors known as it has no iron laminate or axle to weigh it down. It has undergone a UK government review without problems (but no funding).

- We are in phase 2 and make boards like the 100A H-bridge board which can be paralleled to make 1kA to 10kA drivers in a Hypercube configuration for the floating axle motor.

- We making the Lithium management systems to manage the power bank for the Hyper Car and the solar capture devices for the solar panels that line the Hyper Tunnel exterior in Hypercube compact 3D battery systems.

- The prototype vehicles can be largely 3D printed and re-enforced with metal mesh for crash resistance.

- The roll cage is the only item that needs to be built during testing phase. For that we intend to develop parametric design software that can be fed to laser cutter to cut steel which is then welded and/or bolted to make the roll cage.

- The total R&D costs are very low because there are so few moving parts to this new technology.

- The Hypercar will enjoy exponential evolution and growth because like the semiconductor industry, it is more aligned with an industry that makes complex products with no moving parts.

2018-08-14

- Next step is to FDM print the motor in PETG and demo it to focus minds.

2018-08-24

- Magnets arrive for bigger prototype.

- 1 inch in size - but becomes dangerous to handle. Easily inflicts damage to fingers if it pinches skin. Easily flies through the air at several inches away from another magnet!

- Use the 1 inch size magnets with a 3D printed cage to push the speed limits of this motor using 100A H-bridge and STDuino Hypercube boards.

- The rod magnets are for small version prototype of the linear version of the motor. It can be used to build very fast linear actuator. But care needed as the vibrations would shake the device apart - so we going to build it with an active recoil load. Using the 100A Hypercube H-bridge boards and the Hypercube STDuino board for fast prototyping work. Design the gadgets in 3D using parametric design as much as possible.

- The extremely fast linear version with recoil balance we will use to try to make a 3D printer that aims to FDM print a drinking cup in nylon in under a minute.

2018-09-12

- After several iterations we 3D print a hollow rotor in PLA. This is lighter in weight than each magnet :)

- This motor has the world's highest power to weight ratio for an electric motor. It has no axle or bearings and floats in a natural magnetic field of its own making (without need for control board to stabilize it)

- We print it with blades to turn it into something similar to jet engine. Such engines will fly in extremely thin air like the upper atmosphere on Earth or on planets with thin air such as Mars.

- Potentially this engine is better than anything that NASA has to fly on thin atmosphere planets like Mars.

- It can be used as a compact air brake for landing on planets with weak atmosphere. There is no speed limit for the rotor when it spins up, so a solar panel can be used to spin up to maximum kinetic energy that could possibly be stored before it breaks up. As the vehicle attempts to land, some air from the atmosphere is slowed down to below speed of sound, and passed over the device where turbine blades connected to the rotor reside. The turbine transfers kinetic energy of the rotor to the air by opposing the air flow, and slows down the vehicle.

- There is no speed limit for this rotor - at extreme speeds it can bat air out an engine faster than air can move and become supersonic (which may cause it malfunction with turbulence). To avoid supersonic operation and turbulence, extra air such as compressed air or water vapor can be injected into the engine to force it to do more work and thus slow down, and generate a lot more thrust. Burning compressed hydrogen to fossil fuels will produce more steam but thermal problems may damage the engine.

2018-10-08

- There are many Hyperloops. The original systems are more than a 100 years old where a partial vacuum speeds shuttles between departments in pneumatic tubes. The Hyperloops are scaled up versions adding magnetic levitation to carry bigger pod that carries passengers at immense speed. Typically 1 to 2km per second are being sought from the very latest designs. Slower speeds are just as OK if the distances are not too great.

- A precise definition of Hyperloop is now missing from everyone's vocabulary.

- We think Hyperloop Travel means traveling in an evacuated tunnel to minimize the effects of air and weather conditions, where the costs of implementing the system are now within reach of current production technologies.

- Within reach of current technologies is important because previously it would have been doable but very expensive to achieve good results at reasonable expense.

- This definition leaves open the possibility that Hyperloop could be just and evacuated tunnel with self propelled or magnetic levitation drive propelled vehicles traveling down the evacuated tunnel at high speed.

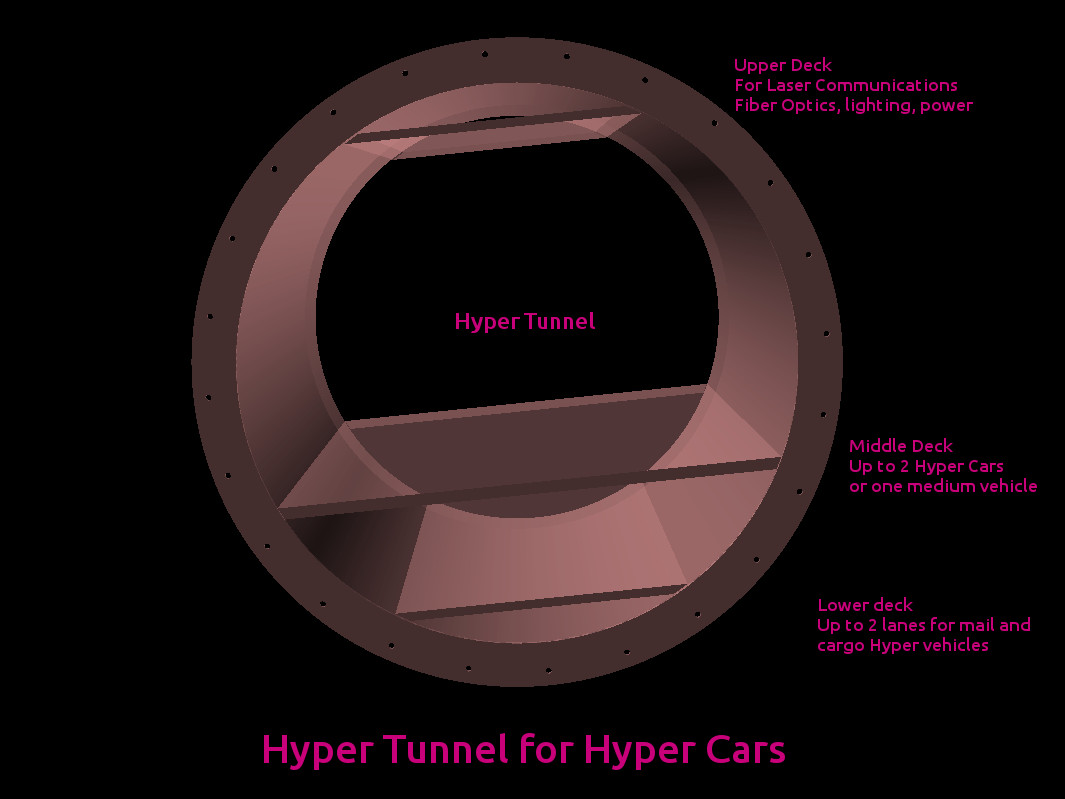

- The above figure is a representation of what could be one version for Hypertunnel

- This version of the Hypertunnel has no magnets, coils or levitation mechanisms built into the evacuated tunnel. This is meant for Hyper Car where the wheels of the car are floating in a magnetic field. Thus the tunnels are devoid of expensive magnets and coils. The magnets and coils are on each vehicle and dependent on size of vehicle. Thus the tunnel can be separated into several levels. The mid level is where the vehicles travel. It can carry just one medium sized vehicle at a time, or two smaller vehicles allowing overtaking. The deck below the road is for parcel and mail pods that whisk goods between cities and between countries in under half day speeding up commerce.

- The very lowest of level carries cables and fiber optics to deliver Internet of Fiber across cities and regions. Likely we leave that space empty if possible to allow any water ingress and debris to be removed by robotic cleaners.

- The very top level also carries cables and fiber optics. The lighting is installed alone that deck. Also installed are laser communications links that maintain constant communications with the vehicles and deduce conditions to take appropriate action by warning and controlling vehicles in front and behind. Since the speed of the vehicles is very fast, most likely the lasers use high speed deflection mechanisms such as galvanometer or a voice coil to control the laser beam direction.

- To reduce costs even further, the design of the Hypertunnel and the initial vehicles that use them are going to be designed with parametric software that has been scripted in a language such as Python. This allows the design to be instantly modified for different sizes of tunnels. The parts for laser cutting or plasma cutting are printed out in seconds to make the complete Hypertunnel.

- We also intend to make the pillars robotic and designed by parametric software to allow them to scale. The robot pillars allow the tunnel to be minutely adjusted in heavy winds, earth quakes and so on without human intervention.

- We intend to make the installation of the robotic pillars to be performed by robots that walk to their work, lift and install the Hypertunnel sections with near zero assistance. The aim being to avoid cutting roads all the way parallel to the Hypertunnel adding huge costs to the overall project.

- The Hypertunnel sections are carried on top of the already built sections of Hypertunnel making the assembly process of the entire Hypertunnel a whole faster.

- Using the Hypercube system we think we can make applications such as all electronics for the vehicles, controls and AI far quicker than anyone else.

- A large part of it going to get developed as open source technology.

Competitors

- The biggest competitors to Hyperloop are the railways and airplanes.

- Railways fear it because they loose their passengers to it, but not their heavy freight traffic

- In reality cars and lorries are bigger competitors so loosing traffic is built into the system

- Hyperloops improve productivity when passengers use it to improve productivity which railways do not mitigate, so there really is no need for railways to fret over loosing passengers because society as a whole is better off, and they can move to reduce passenger trains and concentrate on freight traffic.

- Airplane companies fear Hyperloop because they loose their passengers and mail traffic.

- In reality trains and road vehicles also move their passengers so loosing passengers to alternative modes of transportation is built into the system.

- Hyperloop improves productivity by shortening journeys which airplane travel does not mitigate, so airplane companies need to do some work to move their services to where Hyperloop does not offer a service.

- Car is the greatest mode of transportation humanity has ever engineered. It took 25 years to overtake all other modes of transportation and has never been beaten. Raging against cars and other failed modes of transportation has never ever worked. So it is time to improve the car and take it to the next level. This new level is the Hyper Car. A vehicle that drives on normal axles at low speed, switches to floating magnetic axles when it gains speed, and then travel in a Hyperloop evacuated tunnel on full auto pilot at speeds approaching 1km to 2km per second on floating magnetic axles.

- Hyper Cars will evolve to become Hyper Pods at some time in the future. A Hyper Pod has no steering wheel. It takes you from end to end on the best routes available including use of Hyper Tunnels. It does not need to be owned by you if you are on regular routes on shopping and business trips.

2018-10-09

- We got better giro technology than NASA. 😀

- The motor we have has no axle and thus will never wear down in giro mode. Unlike the failed Hubble Giro

|