|

Home Page

Six Transistor Cache

Investors

Launch Date

Contacts

Terms and Conditions

_________________________

|

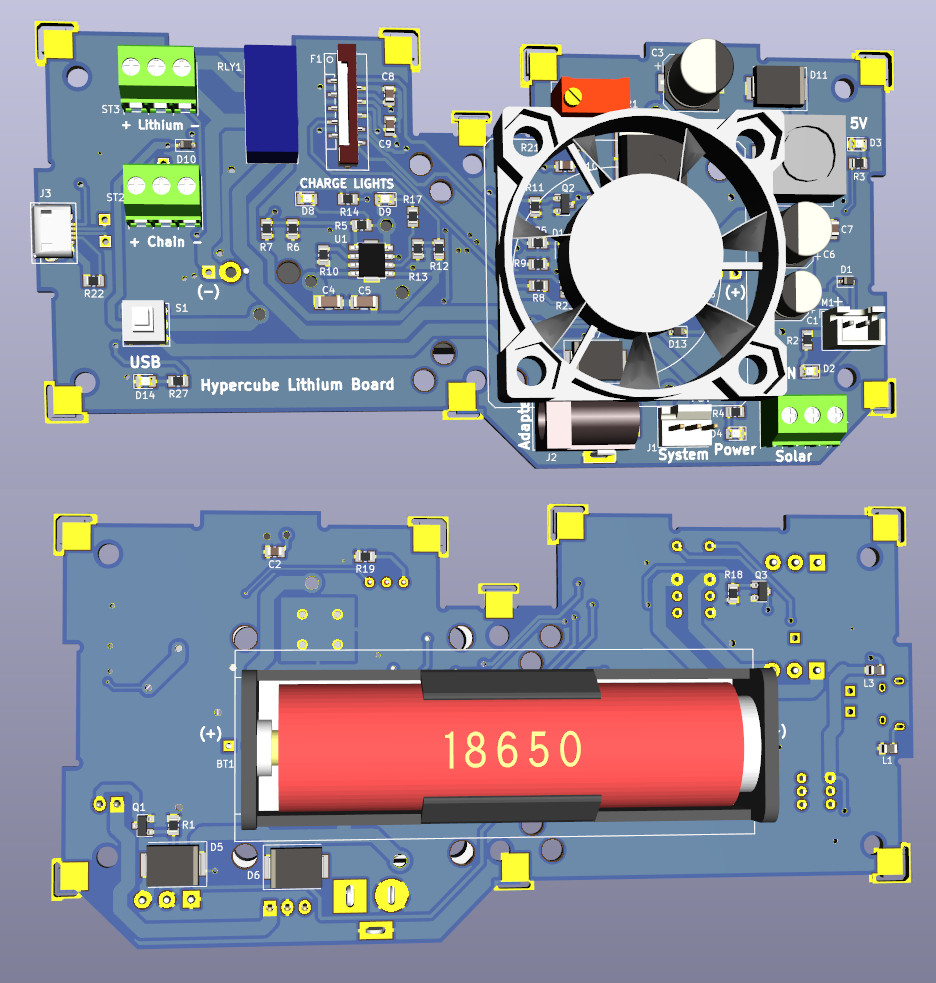

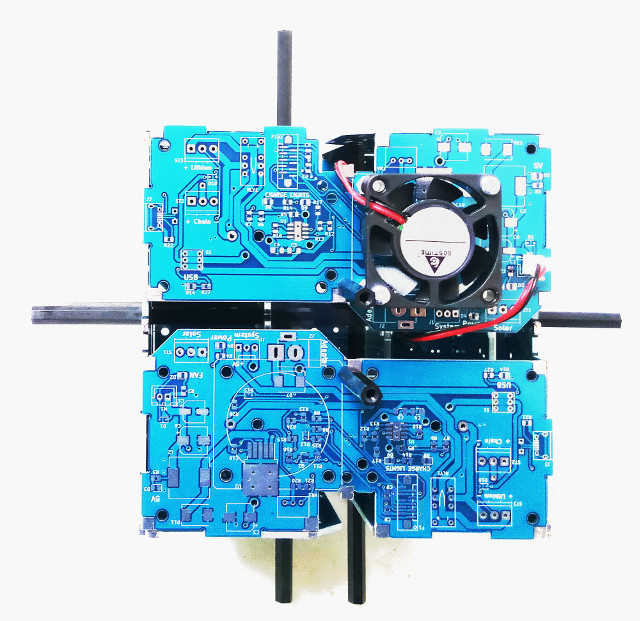

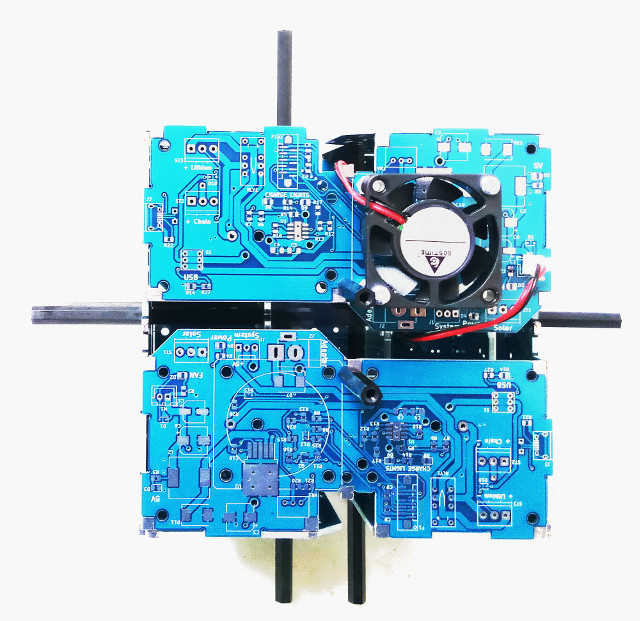

Hypercube Lithium Prototyping Board

- The Hypercube Lithium Charger Board is based around peripheral boards for the open sourced ARM Linux SoC board

- This Lithium charger board has option to fit it with a 40mm cooling fan, remote control relay to switch between normal operation connected into serial battery packs and then into 'balanced' charge mode operation where each battery is charged individually according to its current state of charge.

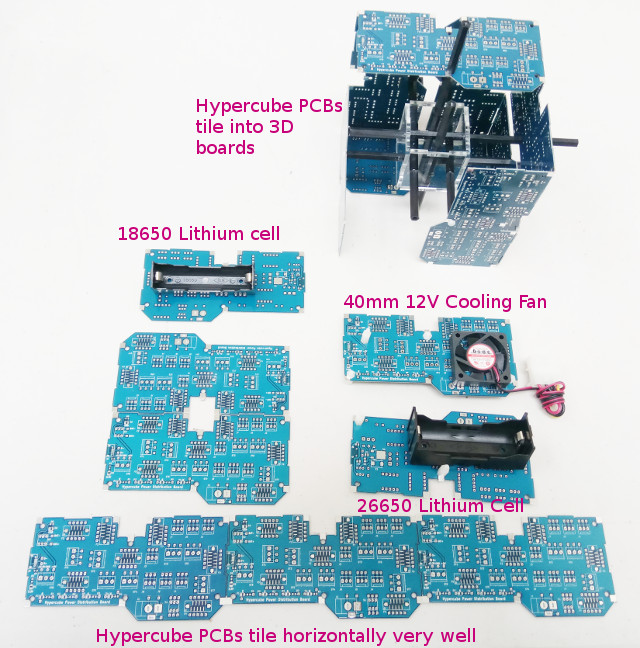

- Hypercube can house twelve 18650 Lithium battery boards. It can also house four 26650 batteries and depending on space.

- (This above is version 2 sent off for new samples)

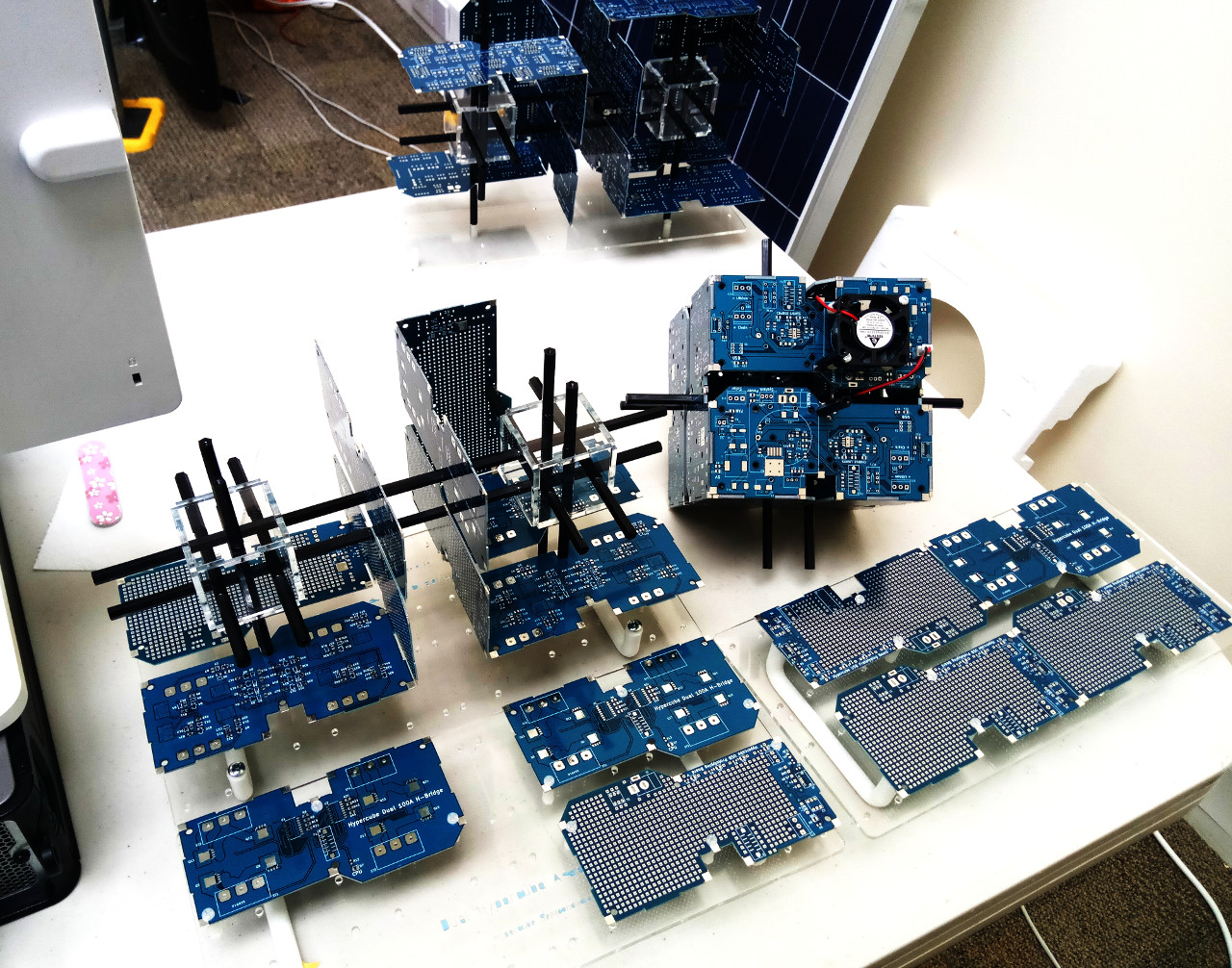

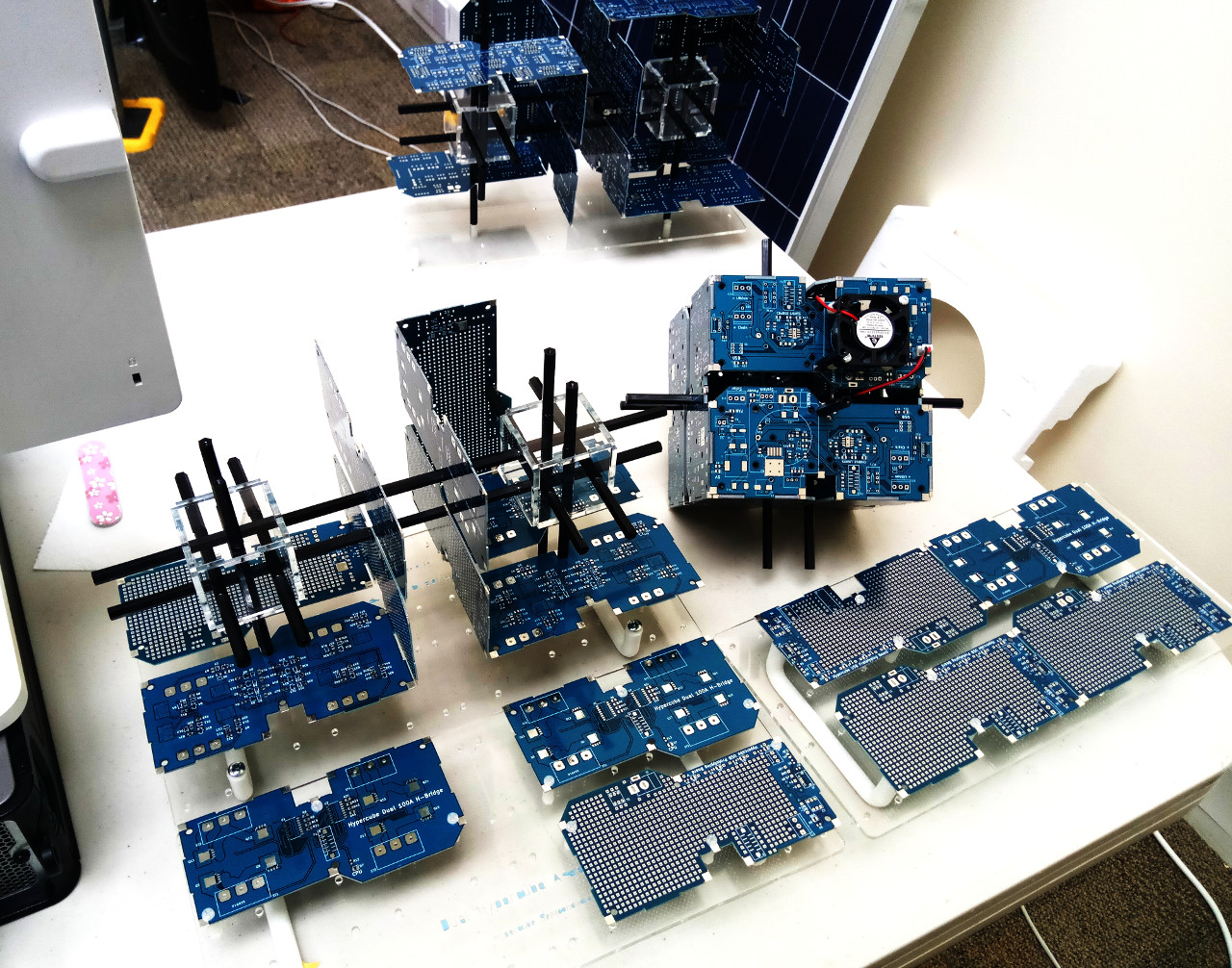

- These boards can be tiled into a very large array

How to make Intelligent Lithium battery packs for autonomous systems

- We don't normally put too much effort into making intelligent battery but this oversight can weaken a whole project that needs to autonomously manage battery power. Particularly for autonomous devices that need to work out how long it can run for. The Hypercube boards are being developed with a view to open sourcing the KiCAD circuits together with ST versions of Arduino software to intelligently control the charger boards.

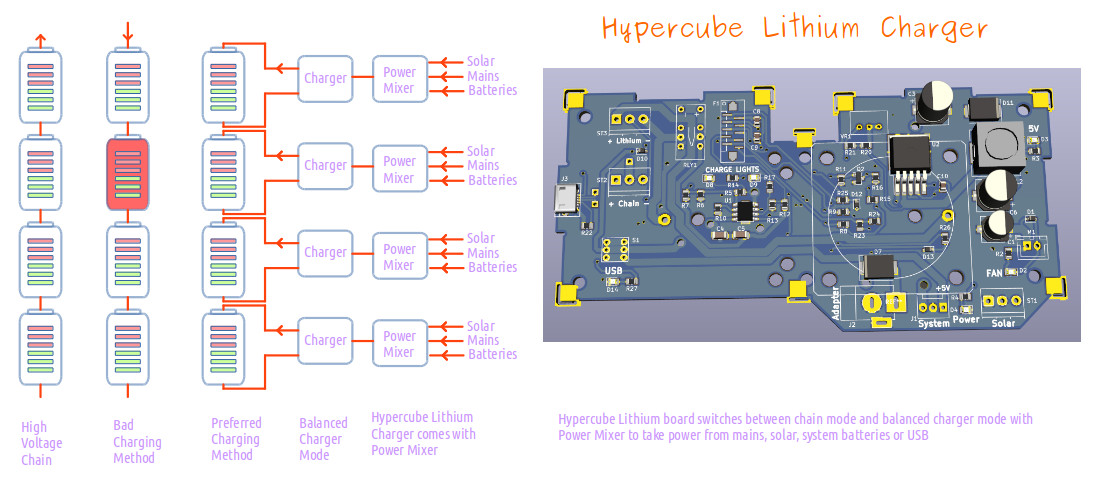

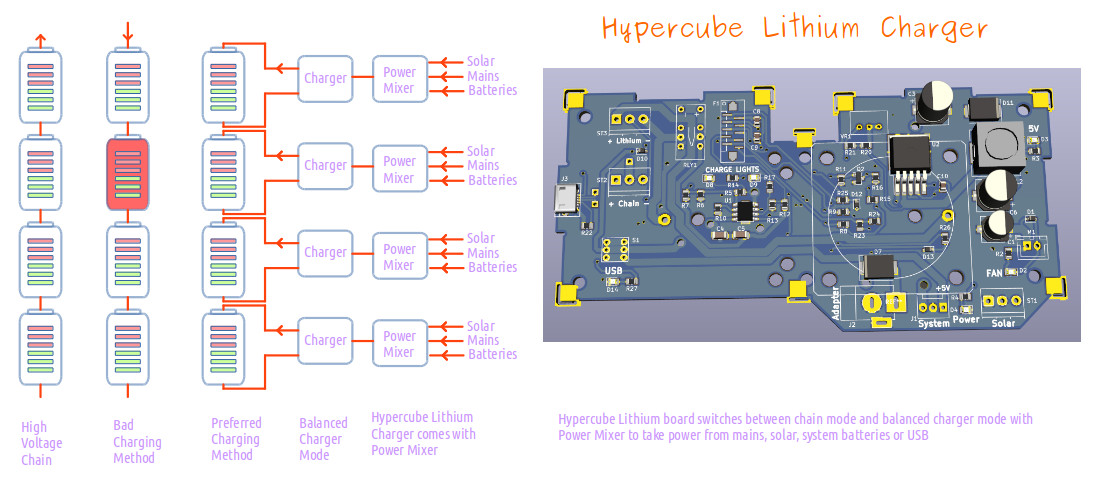

- The problem that needs solution is that batteries need to operate connected in series to generate higher voltages, but each battery would like to be charged individually at low voltage. If we try to charge a long string of batteries at high voltage, one of the cells could be weak or damaged in the string, and this would put the whole battery pack at risk of fire if we try to charge that pack. So each battery in each string of batteries need to be managed separately.

- For longevity, Lithium batteries would like to be charged hot and fast to destroy microscopic needles that might otherwise form when charged slowly and puncture the battery electrolyte chemical separation layers causing a short circuit. The needle formation processes are easy to see if the battery is built from transparent materials in laboratory conditions. The chemical mixtures can be varied to see what changes to materials can be made to mitigate needle formation, but this kind of research and development is a long process. At the same time batteries cannot be charged too hot and too fast because the battery chemistry does not support it. Battery packs need individual thermal sensors to distinguish a damaged battery that is overheating from a battery that is being charged hot and fast.

- A good battery will remain cool despite drinking lots of charging current. An efficient battery is one that remains cold until it is fully charged because if it wastes energy then it will get hot. The charge/discharge cycle with 100% efficiency means the battery never gets warm! Supercapacitors on the other hand cannot do this. Supercapacitors convert a third of the charging energy into heat due to physics. A supercapacitor is never as efficient as a battery. But on the other hand, a supercapacitor can instantly switch between discharge mode to charge mode. So they are very good for absorbing energy from regenerative braking. Batteries cannot compete with supercapacitors here because to go from discharge mode to efficient charging mode takes several minutes to get the battery chemistry to reverse. To mitigate against this problem, the battery strings need to be partitioned into two sets. One set that is discharging, and another set that is charging. Only those that have been charging for a few minutes can efficiently absorb surge power such as those coming from regenerative braking, or solar panels on a cloudy day as the sun gets blocked by chunks of cloud passing overhead.

- The Hypercube Lithium charger prototyping board is designed to take all these scenarios into account with a power mixer. The power mixer accepts mains power, solar power, and battery power. If the system is starting up, it takes all its power from mains. If renewable solar and/or wind generator is connected then providing it is generating more power than minimum mains power, then the power mixer will use solar energy. If there is already a set of charged batteries available, and software has worked out that the battery is not immediately needed, then the charger can use the battery reserves to optimally charge the discharge battery. If solar or wind come on stream as surge power, then the battery drain is automatically cut back to allow the solar power to be maximally absorbed.

- For longevity, batteries should not be left to idle in the fully charged state because that also allows needle formation and quicker deterioration of battery. About 60% is a good starting point. So Intelligent software needs to balance which strings of batteries need a full charge, and which can be left at 60%.

- These numbers are slightly different for different types of Lithium batteries, so the software needs to be customized for different types of Lithium cells according to manufacturer datasheets.

- The way to string batteries into a long chain is to use a DPDT relay to generate high voltage, and when its time for them to be charged, switch the relay on to rewire each cell to individual chargers. These individual chargers can personalize the delivery of charge to each cell and with it bring risk reduction by indicating which cell is not following expected norms. The Intelligent battery pack should also be able to decide which strings are to be charged, and which strings are left supplying power to the autonomous device or vehicle it is providing power for. Adding separate DPDT relays to each string of battery can put them into service if they are safe to use, take them out of service, or take them offline for charging.

- The autonomous device can then decide where and when to get its batteries recharged with the least amount of down time as well as report on any string of batteries with failed cells.

- Sample boards are made now:

- We go on to make software for the battery chargers so that they behave like supercapacitors because they are already in charging mode to absorb as much energy as possible from solar panels (which has variable output voltage and power).

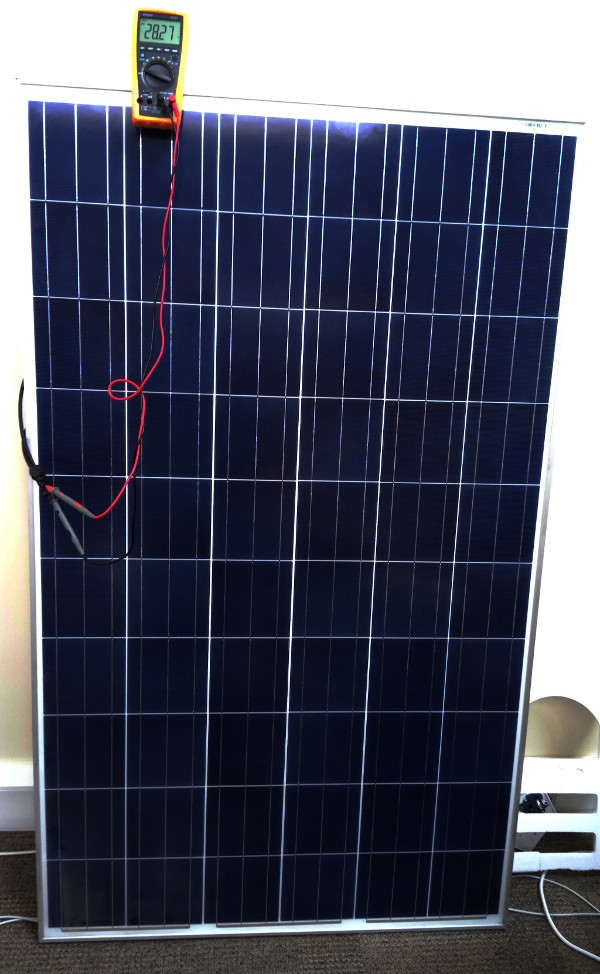

- Solar panel arrive for testings:

Solar Fencing

- One way to increase solar electric generation is to use solar panels built into fencing. At the moment they are about $30 per square meter and dropping in price as new technologies come on to the market.

- Installing solar panels as part of fencing is far cheaper than the price per meter of building a road for example which much also have fencing to protect it from large animals straying onto the road.

- There is opportunity to install two fences down the side of the road, with more added for lane separation fences.

- The power generation may drop from shade, passing vehicles and wrong angles by 50% but the other 50% is still usable.

- Adding built in batteries and splitting into two banks with one bank always charging (as described above) makes the batteries absorb power much more efficiently and they can release it during the night to smooth out the grid.

- Potentially a hundred or so miles can generate gigawatts of energy. The more structures that are covered with solar panels, the more energy.

- Electric power generation companies have been known to resist these options for a very long time and hike electricity costs (e.g. the now defunct Enron), and now seek to hike solar prices by making ownership of solar expensive, and also seeking to prevent the uptake of grid batteries. Its always best not to invite hostile incumbents or their lobbyists to any meetings that involve solar panels, solar fencing, solar buildings, grid batteries or Lithium energy storage devices.

- A solar panel pays for itself and all the energy needed to make it, (and also recycle its glass and aluminum frames in the future) within a few weeks of being installed. The rest is just pure profit for next 20 years. That is why there are so many incumbents out there trying to stop the uptake of solar. Its also why some solar companies claim to fit your panels free and reduce your electricity bills for 20 years where you compulsorily lease your roof to them for the next 20 years. They already made their money in a few weeks and the rest they rely on not telling you about and don't share :)

Grid Batteries

- Solar is 1000% most effective with grid batteries installed. As Elon Musk points out 100x100 square miles of solar enough for USA with a 1x1 sq mile grid battery. Grid batteries turn an unreliable source such as solar or wind to a 100% predictable and reliable source of energy. Overbuild of energy supplies possible, and all of it can be harvested and stored for months on end in grid batteries. This is not possible with any other technology.

- Grid batteries are far more interesting than anyone will let on about. Installing a mini grid battery under your house will allow it absorb all the energy the house needs in summer to release it as needed during the winter. So you can go off grid practically forever if batteries are cheap enough, and energy prices such as those fueled by international oil cartels like OPEC continue to push prices up. (Cartels are illegal for that very same reason.)

- As prices for batteries push towards $100/kwH and then $50/kwH, grid batteries for each house becomes more affordable over a 5 to 10 year period than electricity, gas and fuel prices. The grid battery under you house can charge your car, make hot water for shower and bath, power electric heaters and power the lighting system.

- We will over a period of time show you how to make these kinds of grid batteries and battery management systems which will be open sourced in anticipation of battery prices that are dropping all the time until where it all becomes economical to build your own grid battery (which we roughly estimate to be 3 to 5 years from now).

- We are never going to run of Lithium. Lithium is potentially found everywhere (25th on abundance list) but concentrated sources are mined first. That is why Lithium batteries are so much more of a big thing than other types of batteries. They are also lighter than other batteries which means they can currently drive trucks to fly airplanes. The range is getting bigger all the time - it is not a linear relationship - doubling battery capacity more than doubles range because the the bigger batteries are made differently and waste less space.

Electric Vehicle Battery Management

- The same level of care needs to go into battery management for large vehicles and cars if they are not to catch fire. We are at the point where one charge can take a car 2000 miles. Electric cars have one or two motors and everything else is just light weight and fuel efficient unlike combustion engines which are heavy and full of heavy weight chunks of metal needed for the engine.

- As battery prices come down, it is cheaper to make a 2000 mile car battery than a small battery car because you need to queue up and recharge often wasting your time, whereas a 2000 mile car can go the full journey and be charged at your home during the night when its not in use.

- We will show you how to make these big batteries for big cars. Who knows, someone may go on to build an open sourced vehicle with a laser cutter :)

Driving High Power Drone Motors

- High power drone motors are 3 phase motors.

- The Hypercube Dual H-bridges are actually 4 half bridges that are wired externally to make them into Dual H-bridge

- 3 of the half bridges can be used to drive one 3 phase drone motor

- To drive 4 drone motors require 3 Hypercube Dual H-bridge boards.

- Each half H-bridge can drive 100A load.

- Higher power is possible by paralleling up the half bridges. So 6 Hypercube Dual H-bridge boards can supply up to 200A drive current at around 25V safely.

- The power to the motor is controlled by feeding PWM signals to the MOSFETs so that they are on for a fraction of the time needed to drive them.

- The PWM signals are three phases set 120 degrees apart.

- The kind of signals needed to drive the PWM is easily possible with Arduino for slow drone motors.

- For faster drone motors, the software needs to be written in C.

- The Hypercube STDuino++ board runs both Arduino code and C code. So you can develop test software in Arduino, and progress to C code

- We will be making fully functional multi-tasking code for Arduino mode and C and release it as open source so you can go build the more powerful drones your imagination has set its eyes on :)

- For the Lithium board we write multi-tasking software and release as open source for managing reconfigurable battery arrays. We will be releasing software for different kinds of battery management systems as well so that you can integrate both the drone drivers and the battery management system in true real time multi-tasking systems with open sourced code that we will provide.

- Soon we will release circuit diagrams, documentation and software - watch this space :)

- These Lithium boards are 2mm thick and stronger to resist vibrations from the cooling fan

- Lighter boards will work for drones as the rotors provide a degree of cooling

Winter Power Storage

- Batteries are getting cheaper all the time, and some day it will be feasible to store enough electric power during excess summer months of power generation and gradually use up the stored power in the winter months. In winter, discharged batteries will be re-charged during the day according to how much sunshine there is. But we use more charged batteries than re-charge them hence the need to have extra reserves to last out the winter.

- The battery technologies of today can easily last a full 6 months in the charged state. However, they do need to be isolated from steep environmental temperature changes.

- Battery storage silos could be built that are insulated and keep the heat in from using the batteries to keep the batteries warm when outside temperatures drop.

- If that heat is not enough, some of the batteries can be expended to keep the battery silo warm during winter months to keep battery chemistry in optimal condition.

- Battery silos are far more efficient than fuel tanks. They do not need extra vehicles on the roads to deliver energy unlike fuel oil.

- If there are enough battery silos in the countryside, heat energy can be made available anywhere in any part of the buildings and road ways through simple cables. Under road heating with use of carbon fiber wires allows easy clearing of blocked roads for isolated farms.

- Batteries were an expensive item to produce but it is a relative concept.

- Today Lithium can be extracted from almost anywhere mixed in with other salts (25th most abundant element on Earth) and only 4% inside a battery is Lithium.

- Other competing technologies such as sodium batteries are also viable for battery silo.

- Solid state batteries are the most promising as they have no electrolytes in the mix which means they are unlikely ever to burn. This in turn means, you simply keep buying extra batteries every year and add to your silo for less and less dependence on external supplies of energy.

Highest Efficiency Fuel Conversion To Electrical Energy

- The most efficient conversion of fuel energy is from vaporizing the fuel, mixing it with air and igniting it in a turbo fan chamber. As the fan turns from the expanding hot gases, it is attached to a generator to generate electricity. There a few bearings in total in this engine that generates friction. The rest of energy can be converted to electric power with some 50% to 80% efficiency. All other options are way down in the 15% mark by the time all the losses are totaled up in practical systems.

- This method is valid for jet engines that powers tanks to engines that power experimental cars with 800+ mile range per gallon. If we develop jet engine + generator systems to convert energy from fuel oils to electric, we save a lot of fuel and gain highest efficiency. But all this is reliant on lower cost mass manufactured Lithium batteries. According to China figures, there is no shortage of battery for any purpose for the foreseeable future. So in theory, the price of rechargeable lithium cells or their equivalents will continue to fall to something like $30/kwH and that would be enough to bring about another manufacturing revolution where we abandon the internal combustion engine and replace all engines with ultra-efficient, cheap to mass manufacture turbine engine + generator systems as the power plant that powers everything from vehicles to ocean going ships.

Tests 2018-06-24

- Hypercube Lithium Power Mixer accepts power input from solar, system batteries or mains adapter and switch between them to maintain charging current to batteries so that battery chemistry does not reverse if say solar power suddenly ceased. It switches to sacrificial system batteries as next option, and finally to mains power if that is the only option left. This allows maximum absorption of solar power without reversing battery chemistry which otherwise can take 4 to 20 minutes to start fully charging again if power is cut.

- https://youtu.be/6AT9ct2PvFk

- Effectively, it is also a UPS for a charger :)

Grid Batteries

- Our ultimate aim is to build out large grid batteries and make all the developer systems in Hypercube format for developers to make their own systems.

- Grid batteries have many advantages over mechanical solutions including instant reaction to a critical event such as power shortage in the grid.

- It can also do some things that the grid itself may find difficult to do which is to stabilize the phases when phases are drawing different amounts of current.

- Essentially one or two of the phases are demanding more current than the grid is able to supply and so the grid battery which doesn't have any mechanical components simply diverts more power to the phase that is drawing more current.

- Another option is to deliver the grid batteries containerized for installing at street junctions to power the local streets in the up coming electrification of vehicles.

- Nearly all the big developed and developing countries have set ambitious conversion to electric car to be completed within 10 to 20 years.

- Political systems as usual too slow. Example London of 8 million people in UK have just 300 charging stations (2018) for 8 million people. Even if 300 charging stations a week are built, unlikely it will electrify the whole of London by due date for full electric conversion.

- Also plugging in any more than 7 cars could easily blow the street fuses, if not the local power transformer or the local sub-station.

- To be practical, grid batteries have to be delivered to street junctions and buried where they will provide charge currents as and when demanded from its power banks evenly over the course of the day. This relieves the local sub-station of unimaginable demand as everyone goes home and plugs in their electric vehicles to get charged.

|